A car horn should be loud. They were built that way for a reason. However, over time, you may notice that your car horn sounds weak.

This can especially be the case after a rainstorm. If this is the case, don’t worry – you’re not alone!

In this blog post, we will discuss some of the reasons why your car horn might sound weak, and we will offer some tips on how to fix it. Keep reading to learn more!

Key Takeaway

- A car horn is an auditory signaling device in vehicles that emits a loud sound as a warning or alert to other road users.

- A car horn can sound weak due to a bad horn switch, a faulty horn relay, a blown horn fuse, damaged speaker cones, a wiring issue, or a broken clock spring.

- Testing a car horn involves checking the fuse for any damage, using a multimeter to test the electrical current reaching the horn, and bench testing the horn by connecting it directly to the car battery.

What Is a Car Horn

A car horn is a device installed in vehicles, designed to alert others to the vehicle’s presence or imminent danger with a distinct, audible sound.

The car horn serves as an essential safety tool in driving. It alerts other drivers, pedestrians, and animals of your presence, particularly when they may not see you.

The sound produced by the horn is loud and distinct enough to be heard over ambient noises on busy streets or highways.

In my years as a mechanic, I’ve seen the importance of a functioning car horn. It helps prevent accidents and ensures safe driving.

It’s generally located in the steering wheel for easy access to the driver. When pressed, it completes an electrical circuit that causes the horn to emit sound. This sound is typically loud and abrupt, designed to grab attention quickly.

Car Horn Sounds Weak – 6 Possible Causes For This Issue

A car horn might sound weak due to a variety of issues, including a damaged fuse, defective clock spring, faulty horn button, wiring problems, a bad horn relay, or even a corroded horn ground.

1. A bad horn switch

The horn switch is located on the steering wheel and is responsible for sending an electrical signal to the horn when you press the button. Over time, the switch can become worn out and no longer make good contact. As a result, the electrical signal is not strong enough to activate the horn, resulting in a weak sound.

Horn switches are an essential component of any vehicle. They allow the driver to honk the horn to warn other drivers, pedestrians, or animals of their presence. Horn switches are usually located on the steering wheel, and they are typically activated by pressing a button or by depressing a lever.

Have you ever gone to honk your car horn, only to find that it sounds weak? There are a few reasons why this could be happening, but one of the most common is a bad horn switch.

How To Replace a Bad Horn Switch

1. Disconnect the battery. This will prevent any electrical shorts while you’re working on the car.

2. Locate the horn switch. It is usually located near the steering wheel.

3. Remove the old switch. You may need to use a screwdriver or other tool to remove it.

4. Install the new switch. Make sure it is tight so it doesn’t come loose while you’re driving.

5. Reconnect the battery and test the horn. It should be loud and clear!

If your car horn still sounds weak after replacing the switch, it may be due to a faulty horn. You can have a mechanic check it out and see if it needs to be replaced.

2. A faulty horn relay

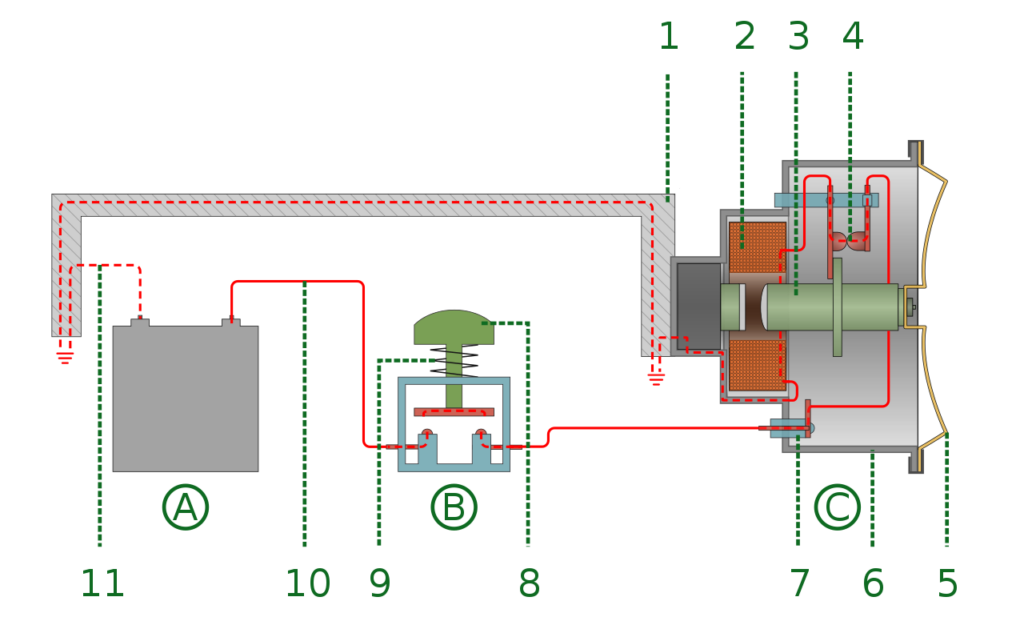

One of the most essential parts of a car horn is the horn relay. It’s a device that helps to control the current flowing to the car horn.

When you press the horn button, it completes the circuit and allows current to flow to the horn. The relay helps to regulate this current, making sure that it doesn’t get too high and damage the horn.

A cause for a weak car horn is a faulty horn relay. The horn relay is responsible for sending an electrical current to the horn, and if it’s not working properly, the horn will sound weak.

When the horn relay becomes faulty, your horn would sound weak or distorted, and eventually, it would stop working altogether.

How To Replace a Faulty Horn Relay

- A new horn relay (available at most auto parts stores)

- A Phillips head screwdriver

- A flathead screwdriver

- An adjustable wrench

1. Locate the horn relay. It should be located near the horn, under the hood of your car.

2. Disconnect the negative battery cable. This will prevent your car from accidentally starting while you’re working on it.

3. Remove the screws that hold the relay in place, using a Phillips head screwdriver.

4. Pull out the old relay and insert the new one in its place. Make sure it’s seated properly and securely in place.

5. Replace the screws that hold the relay in place and tighten them with an adjustable wrench.

6. Reconnect the negative battery cable and test the horn to make sure it’s working properly. If not, check your connections and make sure the new relay is installed correctly.

3. Blown horn fuse

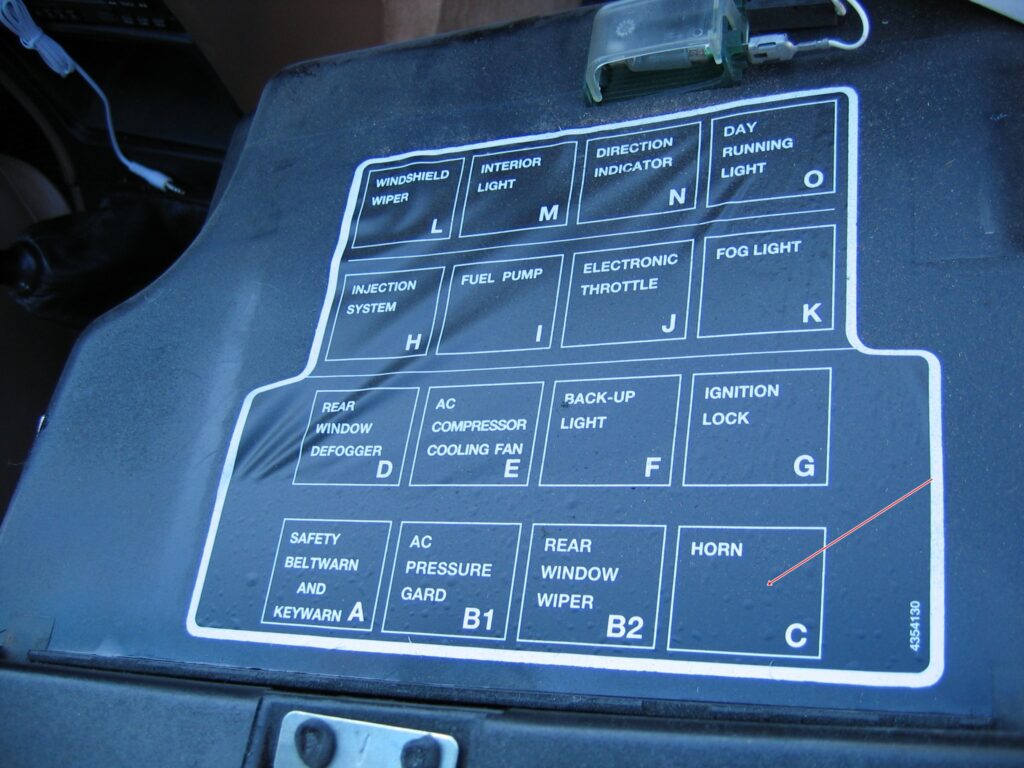

If you notice that your car horn sounds weaker than normal, there’s a chance that the horn fuse has blown. The horn fuse is located in the fuse box, and it provides power to the horn relay. When the fuse blows, it interrupts the circuit and prevents power from reaching the horn relay. As a result, the horn will sound weaker or may not sound at all.

The horn fuse in a car is there to protect the wiring of the horn system. If there is a problem with the wiring, the fuse will blow and prevent any further damage. The fuse is usually located in the engine bay, near the battery.

How To Replace a Blown Horn Fuse

1. Locate the fuse box in your car. It’s usually located under the dash or in the engine compartment.

2. Once you’ve found the fuse box, open it up and locate the fuse for the horn. It should be labeled.

3. If the fuse is blown, replace it with a new one of the same amperage.

4. Close up the fuse box and test out your horn to see if it’s working properly now.

- See also: What Does A Blown 30 Amp Fuse Look Like (With Pictures)

- Read also: What Does a Blown 40 Amp Fuse Look Like (With Pictures)

- See also: What Does a Blown 50 Amp Fuse Look Like (With Pictures)

4. Damaged speaker cones

Car horns are one of the most important safety features of a vehicle. They are used to warn other drivers of potential hazards, and they can also be used to signal for help in an emergency. The loud noise produced by a car horn is generated by a speaker cone.

The speaker cone is made of a stiff material, such as paper or plastic, and it is attached to a metal coil. When the coil is energized by an electric current, it produces a magnetic field that causes the speaker cone to vibrate. This vibration produces the loud noise that is emitted by the car horn.

A damaged speaker cone can cause a horn to sound weak. The cone helps to amplify the sound of the horn, so if it is damaged, the horn will not be as loud.

In addition, a damaged speaker cone can cause the sound of the horn to be distorted. Distortion can make it difficult for other drivers to hear the horn, which could lead to an accident. Therefore, it is important to have the speaker cone repaired if it is damaged.

How To Replace Broken Horn Speaker Cone

1. Remove the old horn speaker cone.

2. Cut a new horn speaker cone from a sheet of paper or cardstock.

3. Attach the new horn speaker cone to the car horn with tape or glue.

4. Test the new horn speaker cone by honking the car horn. If the sound is still weak, try replacing the old horn speaker coil with a new one.

5. A wiring issue

In order to produce sound, a car horn needs to have wires that will carry an electric current. The current will flow through the wires and create a magnetic field. This magnetic field will interact with the metal diaphragm inside the horn, causing it to vibrate.

As the diaphragm vibrates, it will create sound waves that will travel through the air and be heard by the person outside of the car. The pitch of the sound will depend on the frequency of the current flowing through the wires. The louder the sound, the stronger the current will need to be.

If your car horn sounds weak, it could be because the wire that connects the horn button to the horn itself may be loose or frayed.

To check for wiring issues, the first thing you’ll need to do is disconnect the battery. Once the battery is disconnected, you can begin testing various parts of the wiring system to see if there are any breaks or shorts.

If you find any broken wires, simply repair them and see if that solves the problem. If not, then you may need to replace the entire wiring system says Cars From Japan.

6. A broken clock spring

One of the most important parts of your car horn is the clock spring. This small, metal coil is what allows electrical current to flow from the battery to the horn. Without it, your horn would not be able to make any noise.

The clock spring is located inside the steering wheel, and over time it can become worn out or damaged. If this happens, your horn will start to sound weaker and eventually stop working altogether.

Thankfully, replacing a clock spring is a relatively simple and inexpensive repair. If your car horn isn’t sounding as loud as it used to, be sure to check the condition of the clock spring. It may just need to be replaced.

To fix a broken clock spring, you’ll need to remove the broken spring and replace it with a new one. Fortunately, this is a relatively simple task that even novice do-it-yourselfers should be able to handle.

How To Replace a Bad Clock Spring

1. Start by disconnecting the battery. This will prevent you from accidentally electrocuting yourself while working on the horn.

2. Remove the horn’s cover so you can access its internals. On most horns, this will just involve unscrewing a few screws.

3. locate the broken spring and remove it. You may need to use pliers or needle-nose tweezers to grab it.

4. Get a replacement spring from your local auto parts store or online retailer. Make sure it is exactly the same size and shape as the one you removed.

5. Install the new spring in the same position as the old one. Again, pliers or needle-nose tweezers may be helpful here.

6. Reassemble the horn and reconnect the battery. Press the button to test your work – if everything is working properly, you should hear the horn sounding loud and clear!

How To Test a Car Horn

Testing a car horn involves several steps, including checking the fuse, testing the electrical current with a multimeter, and bench-testing the horn itself.

Checking the Fuse

The first step in testing a car horn is to check the fuse. The fuse is a safety device that prevents electrical overloads, and if it’s blown, the horn won’t work. Locate the fuse box, usually under the dashboard or in the engine compartment, and find the fuse associated with the horn. If it’s blown, replace it with a new one of the same rating.

Testing Electrical Current with a Multimeter

Next, use a multimeter to test the electrical current coming to the horn. Set the multimeter to DC voltage, and connect one probe to the negative connector pin on the horn, and the other to the ground of the horn. If the multimeter shows numbers when the horn button is pressed, this means electricity is reaching the horn, indicating that the wiring and switch are functioning correctly.

Bench Testing the Horn

If the fuse is intact and there’s current coming to the horn, but it’s still not working, you can bench test the horn. This involves connecting the horn directly to the car battery. Attach a wire to the connection on the horn, ground the bracket to the negative post of the battery, and run the wire to the positive post. The horn should sound if it’s working properly.

FAQs

Q: Can a bad battery affect the car horn?

A: Yes, a bad battery can affect the car horn. If the battery is weak or dying, it may not provide enough power to properly operate the horn. In this case, replacing the battery should resolve the issue. However, if the battery is not the problem, it is recommended to have a professional inspect the horn and electrical system to determine the root cause.

Q: How can I fix a weak car horn?

A: Fixing a weak car horn depends on the underlying cause. If the horn itself is faulty, it may need to be replaced. If the electrical connection is loose or corroded, it can be cleaned or tightened to improve the sound. In some cases, upgrading to a louder horn may be necessary. It is recommended to consult a professional mechanic to accurately diagnose and fix the issue.

Q: Can a fuse issue cause a weak car horn?

A: Yes, a fuse issue can cause a weak car horn. If the fuse that controls the horn is blown or malfunctioning, it can result in a weak or non-functioning horn. Checking the fuse box and replacing any blown fuses can help restore the horn’s functionality. If the issue persists, it is advisable to seek professional assistance.

Q: Is it possible to increase the volume of my car horn?

A: Yes, it is possible to increase the volume of your car horn. One option is to replace the existing horn with a louder aftermarket horn. These horns are designed to produce a louder sound and can be easily installed in most vehicles. Another option is to add a horn relay, which can provide additional power to the horn, resulting in a louder sound. It is recommended to consult with a professional to ensure the proper installation and compatibility of the new horn.

Q: Can extreme weather conditions affect the car horn?

A: Yes, extreme weather conditions can affect the car horn. Intense cold or heat can cause the horn’s components to contract or expand, leading to changes in the sound or overall performance. In extremely cold temperatures, the horn may temporarily produce a weaker sound until it warms up. Similarly, in extremely hot temperatures, the horn may be less effective due to the expansion of its parts. If the weak horn sound persists beyond normal weather variations, it is advisable to have it inspected by a professional.

Q: Can a dirty horn affect its sound?

A: Yes, a dirty horn can affect its sound. Dust, debris, and road grime can accumulate on the horn’s surface and obstruct the sound output. Cleaning the horn with a soft cloth or brush can help remove any dirt or debris, restoring the sound quality. However, if the sound remains weak even after cleaning, there may be other underlying issues that need to be addressed.

Q: Should I replace the car horn fuse myself?

A: It is possible to replace the car horn fuse yourself, but caution is advised. Before attempting any DIY repairs, it is crucial to consult your car’s manual to locate the fuse box and identify the correct fuse for the horn. It is recommended to use insulated gloves and ensure that the car’s ignition is turned off before replacing the fuse. If you are unsure or uncomfortable with the process, it is best to leave it to a professional.

Conclusion and final thoughts

In conclusion, a weak car horn can be a frustrating and even dangerous problem for drivers.

There are various reasons why a car horn may sound weak, including issues with the wiring or the actual horn mechanism itself.

Knowing how to troubleshoot and fix this issue is important for both safety and convenience on the road.

By following the steps outlined in this blog post, you can identify the cause of a weak car horn and take the necessary steps to fix it.