The 6.7 Cummins requires a low-silicate coolant. The recommended coolant for a 6.7 Cummins is the Fleetguard ES compleat OAT coolant.

As an owner or operator of a 6.7 Cummins, it’s important to use the correct type of coolant for your engine. The wrong type of coolant can cause damage to the engine, reducing performance and potentially leading to costly repairs.

The recommended coolant for the 6.7 Cummins is the fleetguard es compleat oat coolant. This coolant is a low-silicate organic acid technology (oat) that provides the necessary protection to the engine, while also being compatible with other coolants. By using the correct coolant, you can help ensure the longevity and reliability of your engine. It’s important to remember to regularly check and maintain the coolant levels to prevent any potential problems from arising.

Why Cooling Is Critical For A 6.7 Cummins Engine

Maintaining proper coolant levels and using the right type of coolant is crucial for the 6.7 Cummins engine. A failure to do so can lead to overheating, which can cause severe damage to the engine. Coolant needs to have the correct mix of water and antifreeze, as well as the proper additives to prevent rust and corrosion.

It’s also important to flush and change the coolant regularly to prevent buildup and contamination. Neglecting to care for the coolant system can lead to expensive repairs and even engine failure. Proper cooling is not only critical for the longevity of the engine but also for the overall performance of the vehicle.

Regular maintenance and attention to detail with the coolant system can ensure the longevity of the 6.7 Cummins engine.

Importance Of Choosing The Right Coolant For A 6.7 Cummins Engine

A 6.7 Cummins engine is a powerful machine that requires the right coolant to keep it running smoothly. Choosing the correct coolant for your engine is crucial for ensuring its longevity, performance, and fuel efficiency. Failure to use the appropriate coolant can result in corrosion, decreased engine performance, and damage to vital engine components.

To guarantee the optimal performance of your 6.7 Cummins engine, it is vital to adhere to the manufacturer’s recommendations on the type of coolant to use. Neglecting these recommendations can prove costly in the long run and lead to expensive repairs.

It is necessary to choose a high-quality, long-lasting coolant specifically designed for heavy-duty diesel engines to protect your investment and keep your 6.7 Cummins engine running at its best.

Compatibility With The 6.7 Cummins Engine

Cummins engines, such as the 6.7, require a specialized coolant for optimal performance. When selecting a coolant, it’s crucial to choose one that is compatible with the 6.7 Cummins engine. Failing to do so could lead to issues such as overheating or corrosion.

It’s vital to follow the manufacturer’s recommended coolant guidelines and ensure the coolant is free of any contaminants. Also, consider the type of driving conditions your vehicle will encounter and choose a coolant that provides adequate protection for those conditions.

Overall, selecting the right coolant for your 6.7 Cummins engine is essential to maintaining its longevity and performance.

Temperature And Heat Transfer Capabilities

Keeping the temperature of your vehicle’s engine is integral to its performance, and the 6.7 Cummins is no exception. The proper coolant is necessary for heat transfer capabilities and keeping your engine running smoothly. While many diesel engine owners use regular green coolant, it’s crucial to note that the 6.

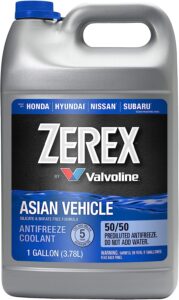

7 Cummins needs an extended-life coolant due to its design. To ensure proper function, use only Cummins-approved coolant, such as fleetguard es compleat oat or zerex g05. These coolants offer the necessary heat transfer capabilities while also providing solid corrosion protection.

Flushing the cooling system regularly and replacing the coolant every 150,000 miles is also key to extending the life of your 6.7 Cummins engine.

Additives And Corrosion Inhibitors

A 6.7 Cummins engine requires a specific type of coolant with the right additives and corrosion inhibitors. It is important to choose the proper coolant to keep the engine running smoothly. The type of coolant required may depend on the vehicle’s manufacturer recommendations or specific engine model.

Additives help prevent corrosion, while inhibitors keep the engine’s internal components protected from wear and tear. It is important to follow the manufacturer’s instructions carefully when choosing a coolant for a 6.7 Cummins engine. Failure to do so can result in premature engine failure, decreased performance, and costly repairs.

Choose a reputable brand of coolant and have it changed regularly to ensure the longevity of your engine.

Flushing And Changing The Coolant In A 6.7 Cummins Engine

Flushing and changing the coolant in a 6.7 Cummins engine is a crucial task that should be carried out at regular intervals. The right coolant for this engine is a fully formulated ethylene glycol-based product containing a low silicate, phosphate-free and nitrite-free formula.

It’s essential to use the recommended coolant because it provides extended protection against cavitation erosion, corrosion, and scale formation. To start the process, first, ensure that the engine is completely cool. Then locate the drain plug, and using a wrench, remove it to drain out the coolant.

Afterward, flush the system with water and refill with the right coolant. Double-check to ensure there are no leaks, and dispose of the coolant properly. Regular coolant maintenance will keep your engine running smoothly and extend its lifespan.

Tips For Extending The Life Of The Coolant In A 6.7 Cummins Engine

Maintaining the coolant in your 6.7 Cummins engine is critical to its longevity. To extend its life, follow these guidelines: check the coolant every six months and replace it after a maximum of five years. Use only specified and compatible coolant recommended by Cummins.

Check the coolant level every week and top it up if required. Inspect the head gasket for damage or leaks. Ensure the engine is entirely drained when replacing the coolant. Refill with distilled water and the specified coolant in the correct ratio.

These simple steps will go a long way in prolonging the life of your engine and ensuring optimal performance.

What Happens If I Mix Different Brands Of Coolants?

A 6.7 Cummins engine requires a particular type of coolant for optimal performance and longevity. If you mix coolants from different brands, it could lead to severe problems. While it may seem harmless, the chemical composition of various coolants can be incompatible, leading to issues such as clogging, corrosion, overheating and damage to the engine’s vital components.

To avoid such adverse effects, follow the manufacturer’s recommended guidelines carefully. Always use the correct type, color, and brand of coolant, and never mix different kinds. Doing so eliminates the risk of incompatibility, reduces engine wear, and keeps your vehicle running smoothly.

Be aware of these precautions when it comes to your engine’s coolant, and you’re sure to keep it well-maintained and functioning at its best.

How Often Should I Change The Coolant In My 6.7 Cummins Engine?

Changing the coolant in your 6.7 Cummins engine is an important part of maintenance. Most manufacturers recommend changing the coolant every two years or 100,000 miles, whichever comes first. However, it’s important to check the owner’s manual for your specific vehicle to ensure you’re following the manufacturer’s recommendations.

The coolant needed for a 6.7 Cummins engine is typically a high-quality ethylene glycol-based coolant, with a mix of water and antifreeze. It’s important to use the correct coolant mixture, as using the wrong type or mix of coolant can cause damage to the engine.

Additionally, using a coolant with too high of a concentration can reduce the engine’s overall performance. Following these guidelines will help ensure the longevity and optimal performance of your 6.7 Cummins engine.

Can I Use Tap Water To Fill My Coolant Reservoir?

To fill your 6.7 Cummins coolant reservoir, tap water might seem like an easy solution. However, it’s not advisable as it can lead to corrosion and engine damage. You should use the recommended coolant type, which is typically a mix of water and antifreeze.

The exact ratio varies by manufacturer, so check your owner’s manual. It’s also important to use distilled water instead of tap water. This removes impurities that could cause damage to your engine. Don’t mix different types of coolant, as this can cause chemical reactions and damage your engine.

Regularly check your coolant levels and top up when necessary to avoid overheating and engine damage.

How Do I Dispose Of Used Coolant?

6.7 Cummins engines require a specific type of coolant that meets certain requirements. Be sure to check your vehicle owner’s manual to confirm the right coolant type. When it comes to disposing of used coolant, you should never pour it down the drain or on the ground.

Used coolant must be collected and disposed of properly. Moreover, it contains harmful chemicals such as heavy metals and toxins that can contaminate groundwater sources and harm the environment. To dispose of used coolant, follow these six guidelines: contact your local waste management facility, use a certified recycling center, never mix coolants, store it properly, use protective gear and carefully transport it to the disposal site.

Disposing of used coolant properly ensures that it doesn’t harm the environment and helps keep our communities healthy.

How Do I Know If My Coolant Is Contaminated?

The 6.7 Cummins engine is compatible with organic acid technology (oat) coolants, which offer improved protection against cavitation and corrosion. Contaminated coolant can cause engine damage and reduced performance, so it’s important to be able to recognize the signs of contamination.

Look out for rust or scale deposits, discolored coolant, and a sweet or sour smelling coolant. A coolant test kit can also be used to check for contamination. Regular coolant changes and using the correct type of coolant can help prolong the life of your engine.

Always consult your vehicle’s owner’s manual for specific information about recommended coolant types and change intervals.

Why Selecting The Perfect Coolant For A 6.7 Cummins Engine Matters

Proper coolant is essential for a 6.7 Cummins engine’s optimal performance. Any wrong selection can lead to significant issues with the engine, including a possible failure. Coolant serves several purposes, including controlling the engine temperature, preventing corrosion and erosion, and reducing cavitation.

A suitable coolant must be compatible with the engine’s metals and be capable of enduring high temperatures, pressures, and extreme ph levels. A coolant containing organic acids is best suited to prevent corrosion and erosion. If your engine requires a coolant change, choose a coolant that adheres to Cummins’ specifications.

Ultimately, choosing the perfect coolant for your 6.7 Cummins engine reduces wear, decreases maintenance costs, and improves longevity.

Recap Of Key Considerations When Selecting A Coolant

Choosing the right coolant for a 6.7 Cummins engine is crucial to avoid potential engine damage. It should be compatible with the engine’s materials and provide excellent protection against freezing, boiling, and corrosion. The majority of 6.7 Cummins engines are designed to run on organic acid technology (oat) or hybrid organic acid technology (hoat) coolants.

It’s critical to consult the owner’s manual or a reputable mechanic to verify which coolant is appropriate for your engine. A mix of distilled water and coolant should be used in a 50/50 ratio. It’s also essential to maintain the proper coolant level and replace it as recommended by the manufacturer.

Remember that high-quality coolant is an investment in the longevity and performance of your engine.

Benefits Of Following A Consistent Coolant Maintenance Plan

Maintaining a consistent coolant plan for your 6.7 Cummins engine is crucial for its optimal performance and longevity. Not only does it prevent engine damage, but it also helps you save on costly repairs in the long run. To ensure that your coolant system runs smoothly, it’s important to follow these six simple guidelines: regularly check the coolant levels, replace the coolant every 50,000 miles, flush the coolant system at least every two years, use the recommended coolant type, avoid mixing different coolant brands, and monitor the coolant temperature.

By sticking to an effective coolant maintenance plan, you can guarantee a longer life span for your 6.7 Cummins engine and enjoy smooth and seamless driving experience.

Frequently Asked Questions On What Coolant Does A 6.7 Cummins Take

What Type Of Coolant Does A 6.7 Cummins Need?

The 6.7 Cummins requires a low silicate ethylene glycol coolant with nitrite, such as fleetguard es compleat oat.

How Often Should I Change The Coolant In My 6.7 Cummins?

It is recommended to change the coolant every 150,000 miles or five years, whichever comes first.

Can I Use Any Type Of Coolant In My 6.7 Cummins?

No, it is important to only use the recommended coolant type for the 6.7 Cummins, such as Fleetguard es compleat oat. Other types may cause damage to the engine.

Conclusion

Based on what we have learned, choosing the right coolant for a 6.7 Cummins engine is no easy task. With all the brands and types available in the market, it can be quite overwhelming to make a decision. But as long as you follow the manufacturer’s recommendation and take into account the engine’s needs and your driving conditions, you can’t go wrong.