If your car’s oil light comes on and the engine subsequently dies, it can be a pretty scary experience. You may not know what to do or where to turn. The oil light comes on when there is an issue with the oil supply. In this article, we will discuss five possible causes of this issue. I will provide some tips on how to remedy it. Hopefully, this information will help you get back on the road as quickly as possible!

When the oil light comes on and the car dies it could be due to low oil pressure, the oil pump has failed, the oil pick-up tube is clogged, the oil filter is clogged, or the oil pressure sensor is faulty. Whatever the cause, the ECU will shut off the engine as a safety measure to prevent engine damage.

Key Takeaway

Why Oil Light Comes On And Car Dies [5 Possible Causes]

- Low oil pressure

- The oil pump has failed

- The oil pick-up tube is clogged

- The oil filter is clogged

- Faulty oil pressure sensor

Why Oil Light Comes On And Car Dies [5 Possible Causes]

![Why Oil Light Comes On And Car Dies [5 Possible Causes]](https://carcarehacks.com/wp-content/uploads/2022/11/Why-Oil-Light-Comes-On-And-Car-Dies-5-Possible-Causes-1024x484.jpg)

If your oil light came on and the car died, there are five possible causes for this.

1. Low oil pressure

![Why Oil Light Comes On And Car Dies [5 Possible Causes]](https://carcarehacks.com/wp-content/uploads/2022/11/Why-Oil-Light-Comes-On-And-Car-Dies-5-Possible-Causes-1-1024x768.jpg)

We’ve all seen it before – you’re driving your car, and suddenly the oil light comes on and the engine dies. It’s an unnerving experience, but fortunately, it generally has a fairly straightforward explanation.

In most cases, when the oil light turns on and your car stops running it means that you have low oil pressure in your vehicle. This is actually a fairly common problem that can be traced to either a leaking gasket, worn internal components such as piston rings, or a number of other possible causes. Low oil pressure can also occur if there isn’t enough oil in the system. So, it’s important to check your levels regularly and top off when necessary.

Understanding the basics of car oil pressure is essential for every driver. An engine needs oil to run its moving parts, and too much or too little can cause serious damage. The oil pressure in a car is determined by two components. The first is the amount of oil flowing through the bearings which lubricate its parts. The second is the viscosity of the oil which ensures it bypasses those parts easily.

Oil pumps circulate oil throughout an engine and develop pressure as they push it against other components while scavenge pumps suck used oil from various points and return it to the sump. A correctly running vehicle has more than enough pressure at idle. But, when you’re driving faster, there needs to be higher levels of pressure so that all moving parts are getting enough lubrication for smooth operation.

Low-pressure warning signs may include excessively high operating temperatures and thrashing or rattling noises which signal impending wear or failure if not identified early on.

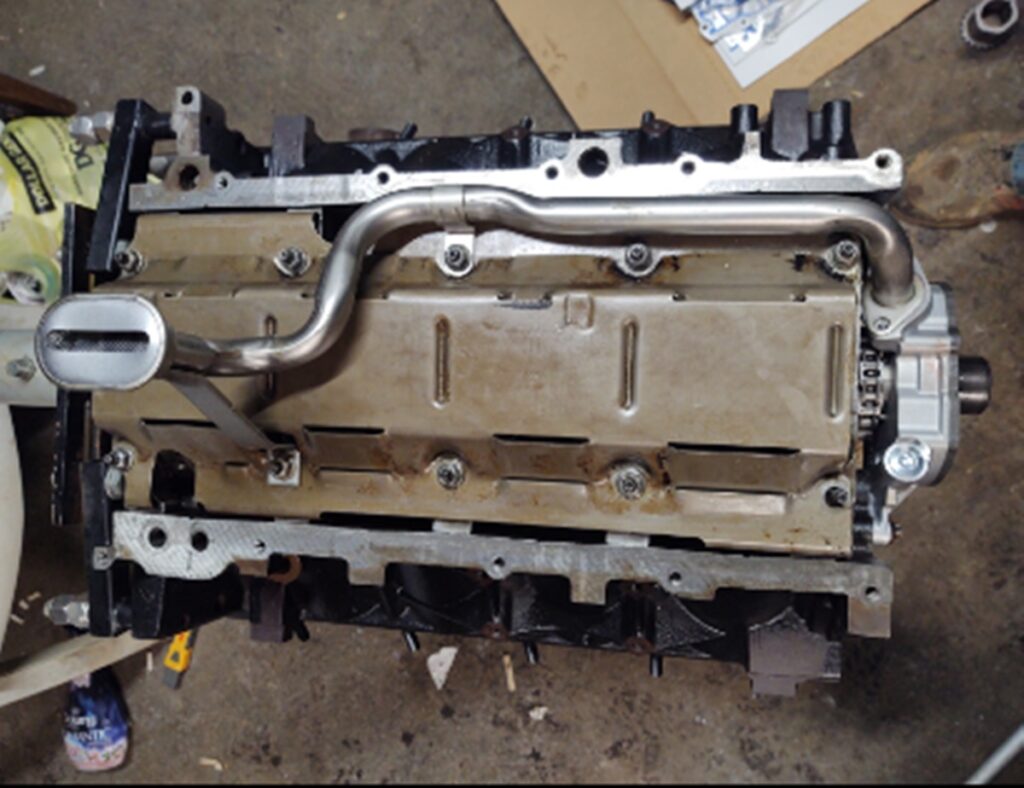

2. The oil pump has failed

![Why Oil Light Comes On And Car Dies [5 Possible Causes]](https://carcarehacks.com/wp-content/uploads/2022/11/Why-Oil-Light-Comes-On-And-Car-Dies-5-Possible-Causes-2.jpg)

When a car’s oil light comes on, it can be an alarming sight, signaling something may be wrong. The most common cause of this warning is a low level of oil in the engine block. It requires just a top-up to rectify the issue. However, an oil light could also indicate a more serious problem. For example, if there is a fault with the car’s oil pressure system then this could be due to a failed oil pump.

An oil pump circulates pressurized motor oil around the engine block and pistons. So, if it fails then it cannot supply enough lubricant for the components to function properly, resulting in increased friction and wear on certain parts of the engine. In this case, the oil light will come on and the car will die.

The job of oil pumps is to draw lubricating oil from the oil pan up into other areas of the engine, where it helps to reduce friction and wear. The oil pump itself is typically powered by a drive shaft connected to one Internal Combustion Engine (ICE) shaft within the engine block.

Oil is drawn in through an intake screen inside the pump housing, then forced out under pressure through passageways and channels to many of the critical parts that need lubrication. To provide sufficient flow, oil pumps tend to be high-pressure devices. They work best when they’re filled with clean oil. This is why it’s important to regularly change your car’s oil filter.

Without a functioning oil pump, a car’s engine can take serious damage and the car will shut off.

3. The oil pick-up tube is clogged

The oil pick-up tube acts like a “straw,” creating suction that sucks oil from the crankcase before going to the filter and lubricating parts of the motor. Its design must carefully balance efficiency against creating too much lift, which can cause aeration of the lube resulting in metal corrosion. In addition to catching excess engine oil, the pick-up tube also helps stabilize temperatures by being cool when it hits the rotating components of your vehicle’s engine – thereby improving its performance under load.

Furthermore, without an effective pick-up tube, dirt and debris can travel through your car’s engine block and harden inside – leading to clogs and potential catastrophic mechanical failure.

When you’re driving and that pesky oil light suddenly comes on and the car dies, do not panic. In most circumstances, the problem can be easily remedied. One of the most common causes is a clogged pick-up tube. This could be due to particles in the oil that have begun settling in the tube, blocking the flow of oil between the pan and the engine. Unfortunately, this issue is often caused by using cheap or low-grade oil or not changing your oil often enough.

Fortunately, with a few simple steps, such as having your oil filter changed and using better-quality oils in the future, you can help prevent it from happening again. To fix an existing blockage, make sure to replace both your oil filter and drain plug gasket before topping off your tank with high-grade motor oil as recommended by your vehicle manufacturer. And if at any point you’re uncertain about what to do next, consult a certified mechanic for advice. They will have plenty of experience dealing with a variety of clogs and obstructions that can cause this kind of issue.

4. The oil filter is clogged

![Why Oil Light Comes On And Car Dies [5 Possible Causes]](https://carcarehacks.com/wp-content/uploads/2022/12/Why-Oil-Light-Comes-On-And-Car-Dies-5-Possible-Causes-1-1024x683.png)

Every car needs oil to keep its engine running smoothly. Without it, the metal parts will rub together and cause significant damage due to heat. As motor oil circulates through the engine components, however, it often picks up dirt and debris that can clog the inner workings of a vehicle.

This is where an oil filter comes in handy. Made out of cloth or paper elements, oil filters help to clean the oil by trapping these harmful particles before they can do damage. When an oil filter becomes clogged up with too much residue, it will cease to be effective and needs to be replaced.

When the oil filter gets clogged, it will restrict the flow of oil inside the engine. This will lead to decreased oil pressure and the oil light will come on. As a safety measure, the vehicle’s computer will then turn off the car in order to prevent engine damage.

Replacing an oil filter isn’t difficult and won’t cost much. The oil filter should be replaced every time you change the engine oil. Taking a preventative approach can help make sure you don’t have any more unpleasant surprises while driving. After all, good maintenance knows no season!

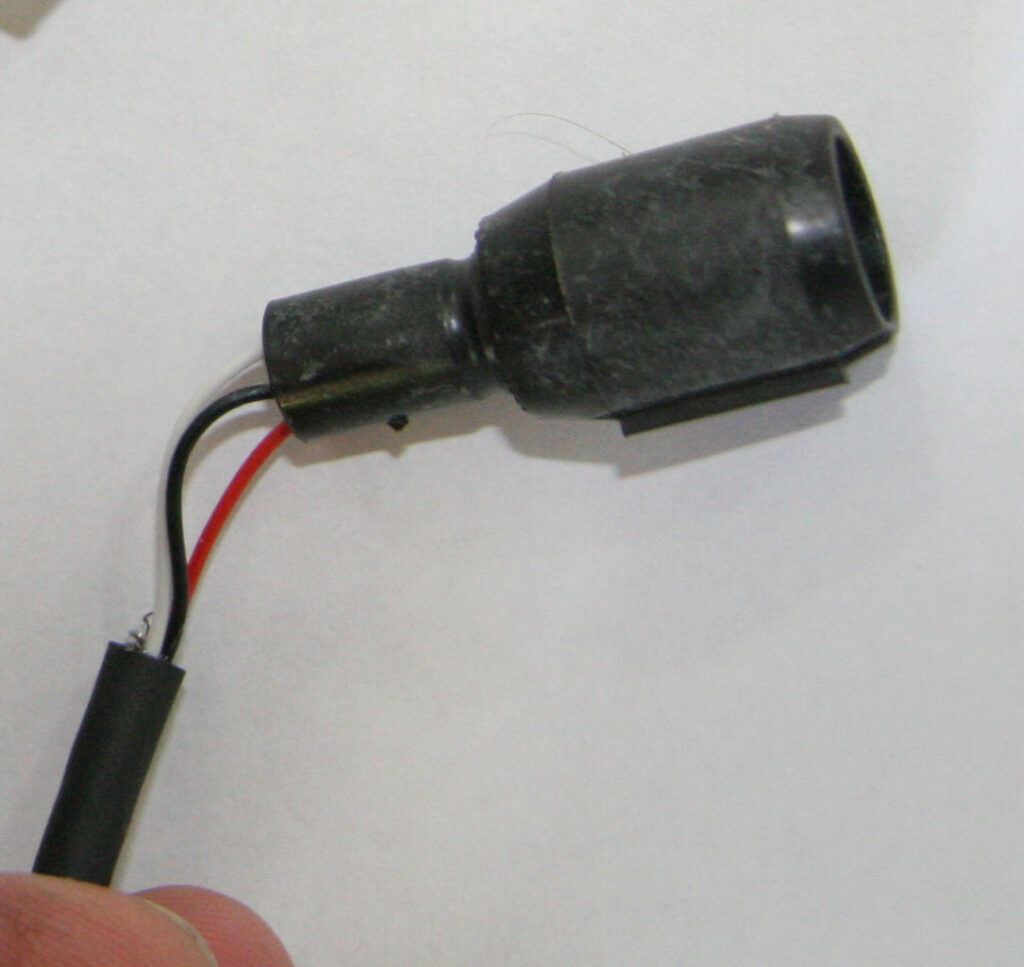

5. Faulty oil pressure sensor

Oil pressure sensors are an essential component of any engines, helping to protect your vehicle and prolong its life. When an engine is running, oil pressure is created by the movement of the pistons in the cylinders. Oil pressure sensors detect this pressure and help to ensure that proper lubrication occurs throughout the engine. If oil pressure drops too low, it can increase the wear on engine components and cause overheating and even costly breakdowns.

When an oil light appears on the dashboard of a vehicle, it’s usually a sign that something is wrong with the oil supply. Sometimes, the oil pressure sensor can become faulty and will start to send incorrect data to the vehicle’s computer. As a result, the vehicle’s computer will think that the oil pressure is low and will immediately shut down the vehicle.

Testing for a faulty oil pressure sensor in cars can be a tricky affair. But, with the right steps, it’s possible to diagnose the issue and get back on the road in no time. First, you’ll need to check the signal output reading. This is the voltage being sent to the sensor from either a dedicated circuit or another component. If it reads lower than normal then it’s likely that the sensor is malfunctioning and needs to be replaced.

There are a few basic tests you can do on your own. These include checking for any visible signs of damage or corrosion on the outside of the part, making sure there’s nothing blocking exhaust flow through channels connecting to the unit, and ensuring wiring harnesses are secure and connected. If these checks don’t turn up any evidence of problems then more specialized diagnostics may need to take place in order to accurately identify what could be an oil pressure sensor fault.